World-Class IMPs. Now Accessible.

THE ONE-STEP

REVOLUTION

Frame. Insulate. Finish. One pass.

Our Products

World-Class Panels

The same IMPs the giants use. Now accessible for your projects.

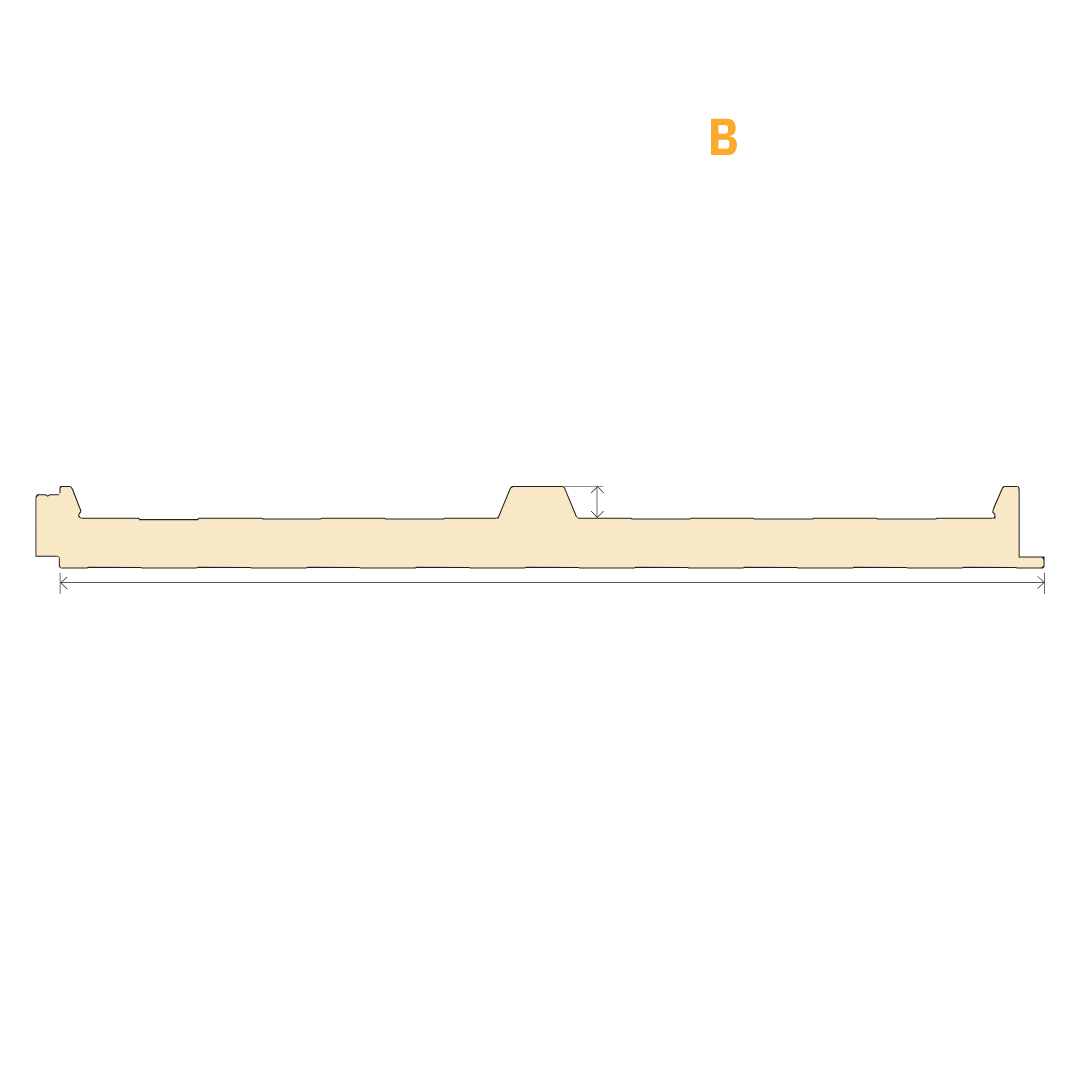

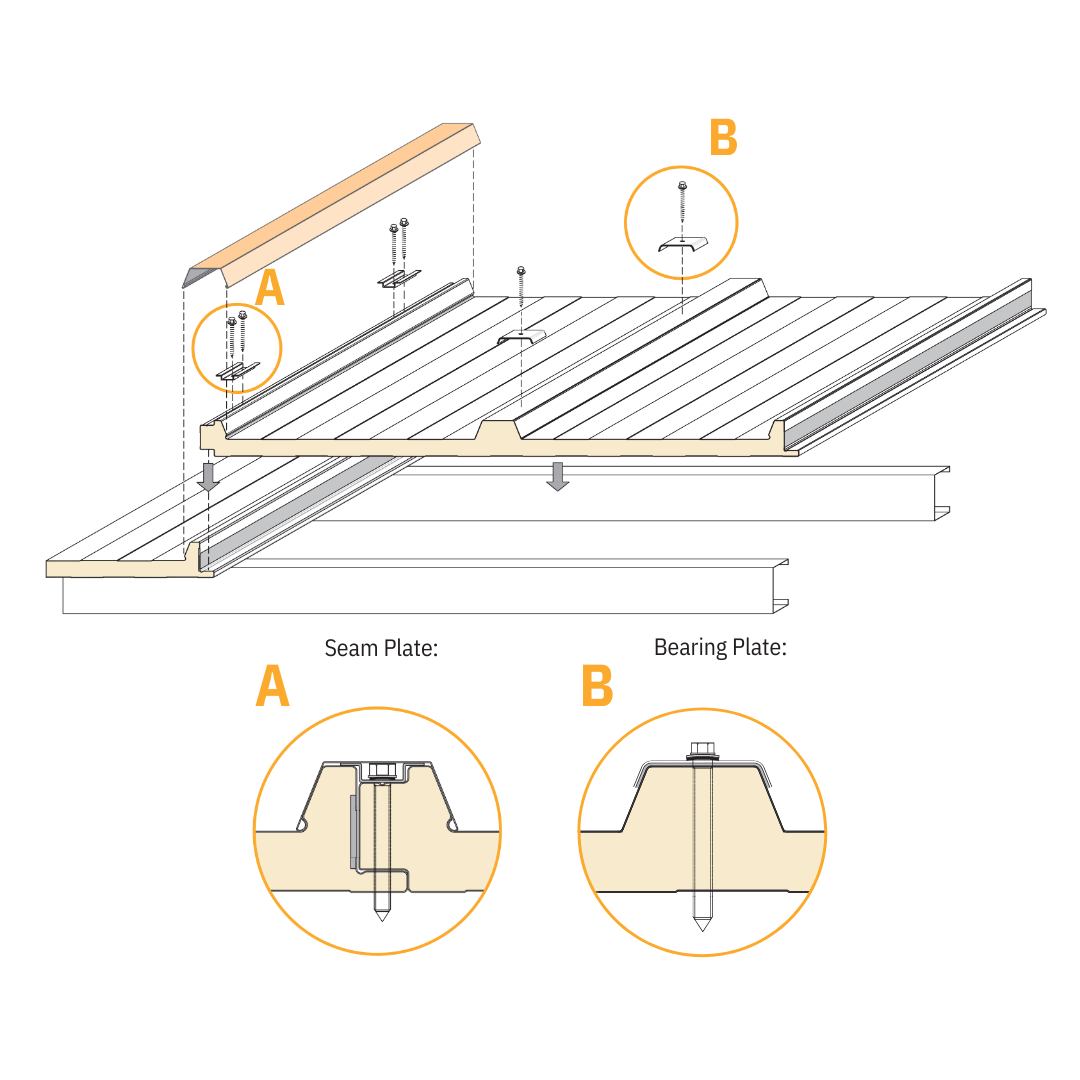

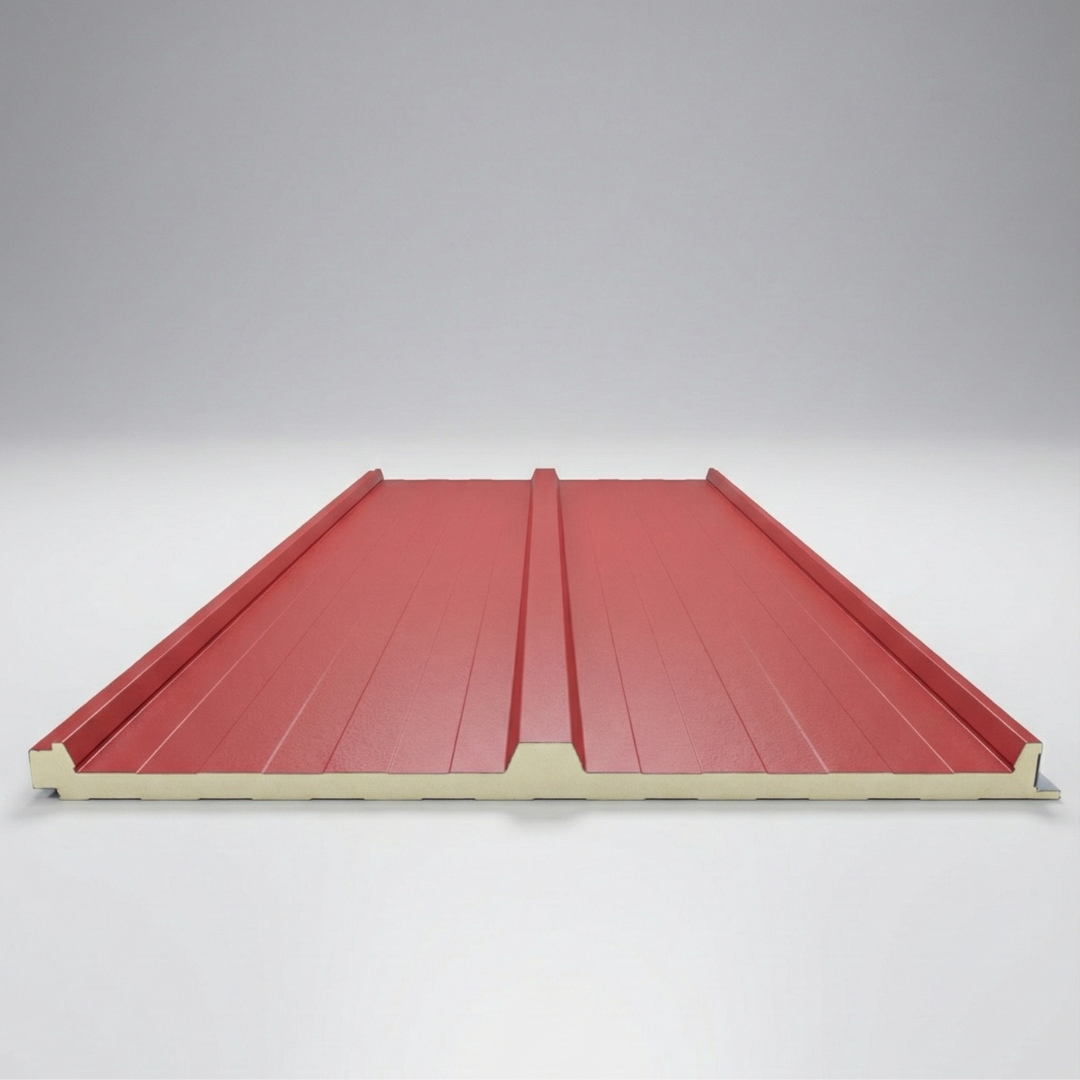

C Series Roof Panel

Four thickness options from 2" to 5" with R-Values from 14 to 33 for optimal thermal performance.

Standard applications

Enhanced thermal performance

High-efficiency buildings

Maximum energy savings

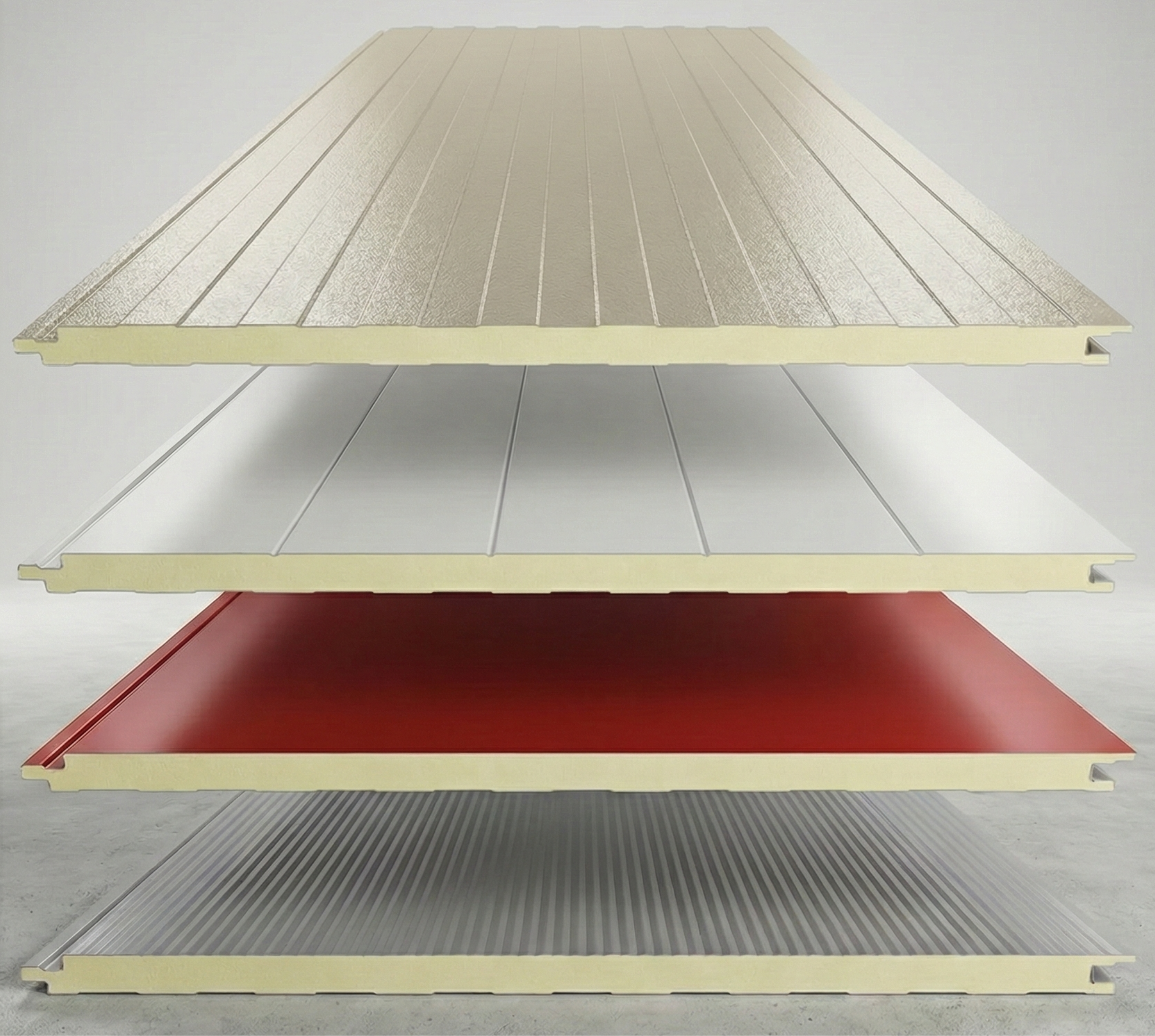

Archiwall Panel

Three thickness options at 2", 3", and 4" with R-Values of 13, 22, and 27 to meet any project requirement.

Standard insulation needs

Enhanced thermal performance

Maximum energy efficiency

Approved for Florida.

Built for Florida.

Our panels carry official Florida Product Approval under the Florida Building Code (FBC) 8th Edition — giving contractors, architects, and building officials the documentation they need to permit with confidence.

- Permits issued faster — no extra engineering review

- Pre-approved for Florida wind & load requirements

- Trusted by inspectors and AHJs statewide

- Reduces liability for contractors and developers

Expert Support

Need technical or installation support?

Our team has 50M+ sq ft of IMP experience. Whether you need code compliance guidance, shop drawings, or on-site installation supervision — we've got you covered.

Our Vision

World-Class Panels for Every Project

For over 15 years, we have delivered high-performance building envelopes for the world's largest projects. Now, we are closing the gap—making elite insulated roof and wall systems accessible to every builder, regardless of project size.

Why Contractors Choose Us

Built for the Job Site

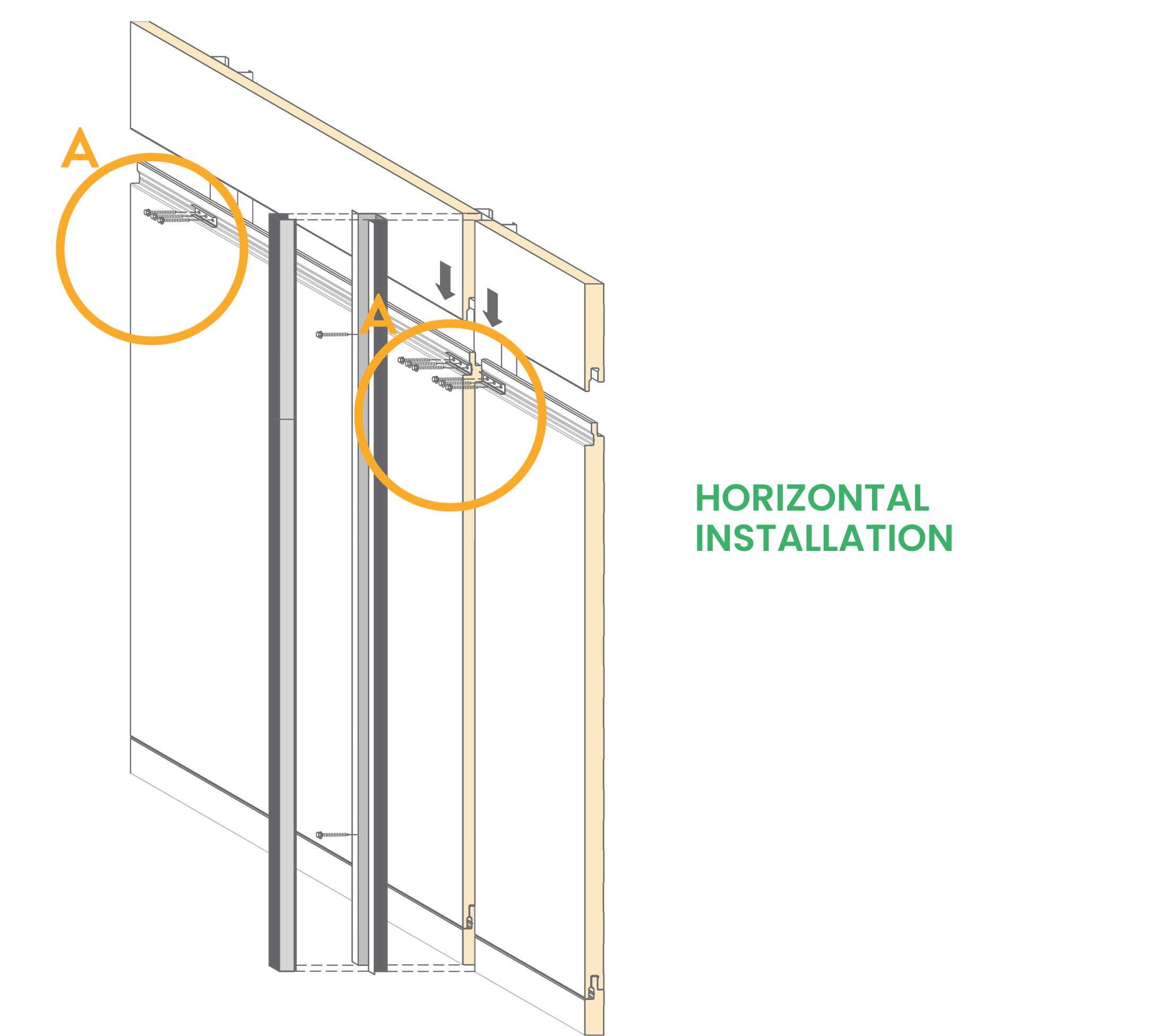

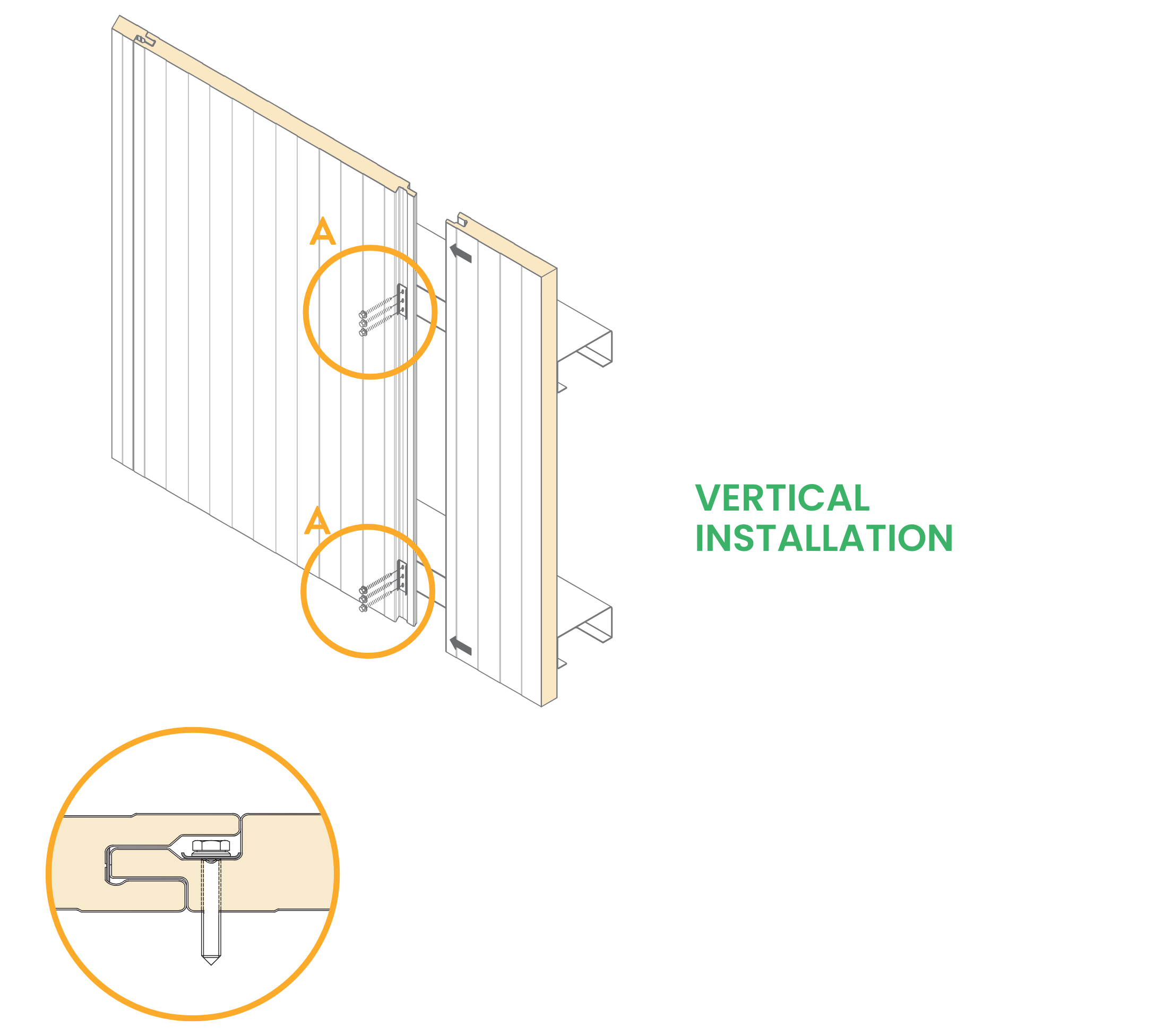

One-Step Install

Structure, insulation, and finish in a single pass.

In Stock

No 12-week waits. Ready when you are.

Class A Rated

ASTM E84 fire rating. Code compliant.

50% Time Savings

Complete projects faster. Move to the next job.

One Single Step Wall Panel

Why Choose IMPs

Traditional vs. Insulated Metal Panels

See why leading builders are switching from multi-step traditional construction to single-step IMP systems

Traditional Construction

8 Separate Steps

Insulated Metal Panels

1 Simple Step

Flexible Solutions

Two Ways to Get Your IMP Panels

Whether you need panels fast or custom-built for your project, we've got you covered

Stock Panels

For Projects Under 2,000 sqft

Ready to ship from our inventory

Perfect for smaller projects and quick turnarounds

Popular sizes and configurations always available

Made-to-Order

For All Other Projects

Built to your exact specifications and lengths

Ships straight to your construction site

Industry standard is 12-14 weeks

Unbeatable lead times mean your project stays on schedule.

Got Questions?

Frequently Asked Questions

Find answers to common questions about our insulated metal panel systems

Product Information

Installation & Performance

Design & Specifications

Ordering & Support

Still have questions? We are here to help.

Our Work

Featured Projects

From backyard builds to commercial warehouses. See what contractors are achieving with Xipre panels.

Industrial Facility

Industrial Complex

Logistics Warehouse

Ezeiza Logistics Hub

Commercial Building

Commercial Complex

Industrial Park

Industrial Zone

Food & Beverage Facility

Food Processing Plant

Laboratory Complex

Research Facility

Hotel Conference Center

Hospitality Complex

Warehouse Facility

Logistics Hub

Have a project you'd like to share?

IMP Consulting & Project Management

Your insulated metal panel and PEMB expert team — on demand. With 50 million+ square feet of IMP deployed across North America, South America, Europe, and Antarctica, we bring unmatched field experience to every project. Streamline costs, reduce risk, and embed IMP specialists who have actually built what they advise on.

15+

Years in IMP

50M+

Sq Ft Deployed

4

Continents

100+

Projects Delivered

What We Offer

Expert Services, One Team

From first sketch to final walkthrough. A dedicated team of IMP specialists managing every detail of your building envelope.

IMP Project Management

End-to-end project oversight for insulated metal panel installations. We coordinate procurement, scheduling, and quality control so your build stays on time and on budget.

Construction Supervision

On-site supervision by IMP specialists who have managed installations across three continents. We catch issues before they become costly rework.

Engineering & Detailing

Panel layout engineering, thermal performance calculations, and installation detailing. We ensure your envelope meets code, performance targets, and aesthetic goals.

PEMB + IMP Integration

Specialized consulting for pre-engineered metal buildings with IMP cladding. We bridge the gap between structural and envelope teams for a seamless build.

Proven Track Record

Projects We've Managed

Real projects, real results. From industrial parks to cold storage — our team has delivered IMP solutions at scale.

Logistics Hub

Full IMP Envelope

Industrial Complex

Roof & Wall Systems

Laboratory Facility

Controlled Environment

Food & Beverage Plant

Cold Storage Panels

Commercial Center

Architectural Walls

Industrial Park

Multi-Building Scope

The Xipre Advantage

Why Hire Xipre as Your IMP Consultant?

The U.S. insulated metal panel market is projected to reach $5.98 billion by 2032. As demand surges for energy-efficient building envelopes in warehousing, cold storage, and data centers, the need for experienced IMP project managers and PEMB consultants has never been greater. With 50M+ sq ft deployed, Xipre fills that gap with proven field expertise.

We Build What We Consult On

Unlike typical project management firms, we manufacture and install insulated metal panels. Our IMP consulting is grounded in 50M+ sq ft of hands-on deployment, not just theory.

Four Continents of Experience

From warehouses in North America to research stations in Antarctica, and projects across Latin America and Europe — we bring global IMP best practices to every engagement.

Single Source of Truth

IMP engineering, procurement, construction supervision, and project management under one team. Fewer handoffs mean fewer errors and lower total cost of ownership.

Cost Optimization for IMP & PEMB

Our deep supply-chain knowledge in insulated metal panels and pre-engineered metal buildings helps you avoid overspecification, reduce waste, and secure competitive pricing.

Global Presence

One Team, Three Markets

Xipre operates across the Americas and Europe, bringing a unique international perspective to every IMP project. Connect with us:

Xipre USA

IMP panels, consulting, and project management for the US market.

xipreusa.comXipre Argentina

IMP manufacturing and construction services across Latin America.

xipre.com.arXipre Spain

European operations with IMP expertise for the Spanish and EU markets.

xipre.esLed by Dario Pussetto

Founder & IMP Specialist

With over 15 years and 50 million+ square feet of insulated metal panels deployed across four continents — from North America to Antarctica — Dario brings a rare combination of IMP manufacturing knowledge, PEMB field experience, and construction project leadership. His team has managed logistics warehouses, cold storage facilities, food processing plants, laboratories, hospitality projects, and industrial parks.

Connect on LinkedInFrequently Asked Questions

IMP Consulting & Project Management FAQ

What does an IMP project manager do?

An IMP (Insulated Metal Panel) project manager oversees the entire lifecycle of panel installation projects — from procurement and engineering to on-site supervision and quality control. At Xipre, our project managers have hands-on experience with 50M+ sq ft of IMP deployed across North America, South America, Europe, and Antarctica.

Why should I hire an IMP consultant instead of a general construction PM?

Insulated metal panel projects require specialized knowledge of thermal performance, panel detailing, continuous insulation, and building envelope integration. A general PM may miss critical details that lead to costly rework. Xipre's IMP consultants are specialists who manufacture, engineer, and install the panels they advise on — reducing risk and total project cost.

What types of projects does Xipre manage?

We manage IMP projects for warehouses, logistics centers, cold storage facilities, food processing plants, laboratories, data centers, hospitality buildings, industrial parks, commercial retail spaces, and even extreme-environment installations like our Antarctic base project. Our experience spans PEMB (Pre-Engineered Metal Buildings) and conventional construction.

How much IMP has Xipre deployed?

Xipre has deployed more than 50 million square feet of insulated metal panels worldwide — from North America to Antarctica, across Latin America and Europe. This is one of the largest track records of any IMP-focused project management firm.

Can Xipre provide IMP project managers for recruiting firms?

Yes. We work with recruiting firms and staffing agencies looking for experienced IMP and PEMB project managers. Our team has the field experience, certifications, and engineering background that top general contractors and owners require for their metal building projects.

What areas does Xipre serve?

Xipre USA is based in Tampa Bay, Florida and serves the entire United States. Through our offices in Argentina (xipre.com.ar) and Spain (xipre.es), we also provide IMP consulting and project management across Latin America and Europe.

Need an IMP Project Manager on Your Team?

Whether you're a general contractor, an owner-developer, a PEMB manufacturer, or a recruiting firm searching for specialized insulated metal panel project managers with real-world experience — we're ready to deploy.

Get Started

Ready to Build?

No minimum orders. No long waits. Just panels, ready when you need them.

The Xipre Advantage

- Order what you need - no huge minimums

- In stock and ready to ship

- Technical support from pros

- Backyard to commercial projects

CHECK PRICE & AVAILABILITY

Tell us about your project and get pricing details fast.